|

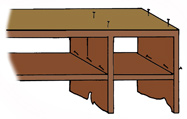

FIG. 1 - You can make

basic, non-adjustable shelving from solid boards of many sizes and widths.

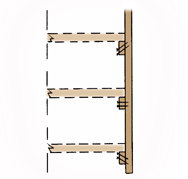

FIG. 2 - Small cleats

make supports for non-adjustable shelves.

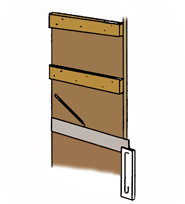

FIG. 3 - The way the

nails are driven affects the strength of a shelf bracket.

FIG. 4 - Larger cleats

provide stronger supports for shelves that must carry heavy loads.

|

ADJUSTABLE AND NON-ADJUSTABLE

WOOD SHELVING

- Additional shelving is useful in almost every home and can be added quickly

and easily. And it need not be expensive.

- Consider adding shelves in your basement, attic, kitchen and other

areas to help keep stored materials much neater and to save time when

looking for stored items.

- You can make basic, non-adjustable shelving from solid boards of almost

any size or width (Fig. 1). Such shelving is easy to make and provides

adequate support for normal storage and shelving needs.

- The disadvantage of non-adjustable shelving is that some stored objects

may be too tall or short, thus wasting space on the shelving you construct.

- You can overcome this problem by making shelves for tall objects and other

shelves for short objects. Give a little thought to the materials you

plan to store so you can design the shelves to minimize wasted space.

- Non-adjustable shelving is normally used in closets, attics, basements,

work areas, etc., where appearance and adjustability are not very important.

These shelves can be nailed together with support pieces to provide

the structural strength required.

- Small cleats can provide the needed support for other types of non-adjustable

shelves (Fig. 2). These shelves can be made as wide or as long as necessary.

- Wood shelving of this type should have supports every 3'. If the shelving

will hold extremely heavy loads, use supports as frequently as every

2-1/2'.

- Use extreme care when nailing the cleats onto the side boards. Use a T-square

or a level to make sure the shelves are in the proper position and are

evenly spaced at all points.

- The way in which you drive the nails will increase or decrease the ability

of the shelves to carry heavy loads (Fig. 3).

- For example, nails driven at an upward angle are likely to pull out when

a heavy load is placed on them.

- If the nails are driven straight into the supporting wall, the cleat has

a fair supporting strength. However, nails driven at a downward angle

greatly increase the ability of the cleat to carry a heavy load. Keep

this in mind when nailing cleats for supporting shelves.

- Wider cleats, as shown in Fig. 4, provide a great deal of structural strength.

They also make it possible for the shelves to be moved in and out as

necessary.

- If you are designing shelves to carry extremely heavy loads, use wide cleats and nail them firmly into position.

|