|

INSTALLING THE NEW HEATER

- Move your new heater to its location by "walking" it or by using an appliance cart, dolly, or hand truck.

- Position the new heater so your piping-particularly a gas vent pipe-will reach most easily.

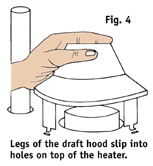

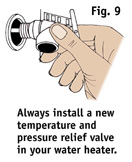

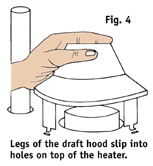

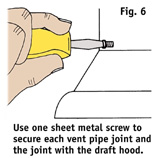

- For a gas heater, install the heater's new draft hood. Many heaters have legs that insert into holes on the heater's top (Fig. 4). Every gas water heater needs proper venting that's no smaller than the draft hood collar of the new heater. It's a good idea to use new vent pipe elbows, since the old ones are probably corroded at their present angles. The vent should go straight up as far as possible. Any horizontal run in the vent should slope upward at least 1/4" per foot, as shown in Fig. 5. Connect the vent pipe with short sheet metal screws (Fig. 6). Be sure to check your local code.

- Now you can make the hot and cold water connections. The type of materials you use will depend on your local code and the type of material used in the existing system. One of the easiest ways to make these connections is using flex-connectors. Flex-connectors are easy to bend to reach the connection.

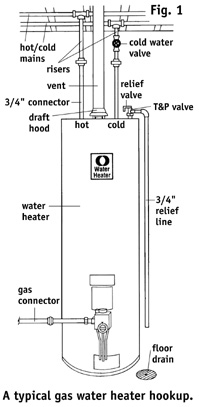

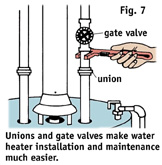

- The water piping is handled depending on whether your house has threaded metal, sweat-soldered copper, or thermoplastic piping, and whether the piping is 3/4" or 1/2". Whatever the piping, the heater should be fitted with a cold water gate valve (Fig. 7). Place the valve in a vertical section of piping to keep it from becoming fouled with sediment.

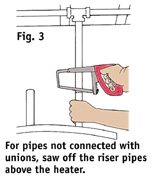

- For threaded pipe, you should have a union on both the hot and cold water lines. Old unions should be replaced. The two halves of a union are manufactured to fit together properly; replace the entire union. You will need new nipples for the top of the water heater. Their length will depend on the distance from the fittings on the top of the water heater to the unions. Allow for the distance the pipe threads into the fittings.

- Unions are not necessary with flex-connectors. Use Teflon tape (but not pipe dope) on the male threads entering the flex-connectors. If your water heater has female-threaded tappings, you'll need a pair of 3/4" nipples to accept the flex-connectors at the bottom. If the heater comes with 3/4" male-threaded stubs, the nipples are not needed. At the top, the flex-connectors fit directly to the ends of the threaded pipes (or a male adapter for converting to copper or plastic). Some flex-connectors install to copper tubing without sweat-soldering. If you sweat-solder, be sure to do this before installing the flex-connectors to avoid damage to the connector gaskets. Your local code may not allow you to use flex connectors. Be sure and check to make sure.

- Thermoplastic pipe. Flex-connectors are not necessary with CPVC or PB plastic pipe. You'll need "transition unions" between the metal heater threads and the plastic piping. Some codes and some plastic fitting manufacturers also call for using steel nipples between the water heater and the transition unions to distance the unions from conducted burner heat. You can use rigid CPVC tubing, solvent welding the joints. Or you can use flexible PB pipe, joining the joints with mechanical couplings (Fig. 8). PB cannot be solvent welded. Don't try to hook up a water heater with PVC, PE, or ABS plastic piping, since these will not take hot water.

|