|

||

|

||

|

|

||

|

||

|

||

|

|

||

|

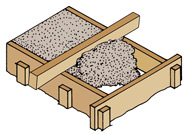

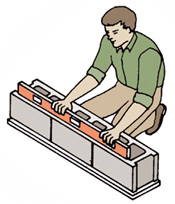

FIG. 1 - Select the correct blocks before beginning the job. |

SELECT THE RIGHT BLOCKS FOR THE JOB

|

|

|

|

|

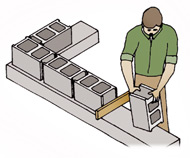

FIG. 2 - Pour a footing of concrete for any block wall.  FIG. 3 - Use a 2x4 or other straightedge to level the concrete. |

POURING THE FOOTING FOR A BLOCK WALL

|

|

|

|

|

ESTIMATING BLOCKS AND MORTAR NEEDED

|

||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||

|

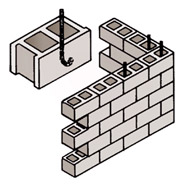

FIG. 5 - Locate the exact corner by stretching lines from one corner form to the other. The two lines cross at the exact center.  FIG. 6 - Lay out a dry test run to determine the number of concrete blocks needed. Use 3/8" plywood pieces between blocks to fill in the mortar. |

PREPARING TO LAY THE CONCRETE BLOCKS

|

|

|

|

|

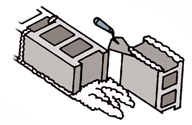

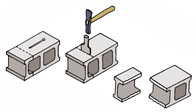

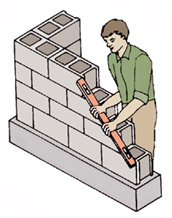

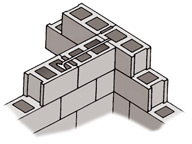

FIG. 7 - Spread the mortar about 1" deep and 8" wide, using a furrow in the center to force the mortar to the edge.  FIG. 8 - After spreading the mortar on the footing, apply mortar to the ends of the blocks.  FIG. 9 - To cut blocks, use a wide chisel and bricklayer's hammer.  FIG. 10 - Check the alignment with a long mason's level after a few blocks are laid. Check the tops and the outside edge.  FIG. 11 - The block corners should strike evenly along a level held diagonally.  FIG. 12 - Set anchor bolts every 3' to 4' in the top run if wood framing is to be applied.  FIG. 13 - Load-bearing walls should be anchored with metal tie bars. |

LAYING THE CONCRETE BLOCKS

|

|

|

|

Trowel

Wheelbarrow

Garden Hose

100' of Cord

3/8" Plywood

Anchor Bolts

Drain Tile

1/2" Galvanized

Hardware Cloth

5/8" Plywood

Mortar

Carpenter's Square

Masonry Chisel

Work Gloves

Mortar Hoe

Galvanized or Plastic Pail

2x4s for Framing

Plumb Bob

Tie-in Bars

Jointer

Mortar Board

Check your state and local codes before starting any project. Follow all safety precautions. Information in this document has been furnished by the National Retail Hardware Association (NRHA) and associated contributors. Every effort has been made to ensure accuracy and safety. Neither NRHA, any contributor nor the retailer can be held responsible for damages or injuries resulting from the use of the information in this document.