|

||

|

||

|

|

||

|

||

|

||

|

|

||

|

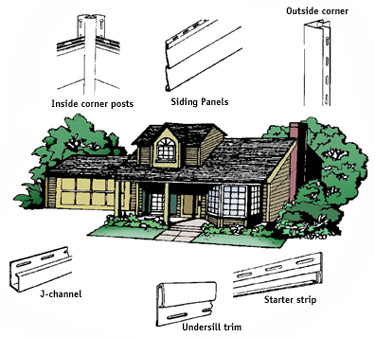

FIG. 2 |

VINYL SIDING

|

|

|

|

|

FIG. 3 - Find the sum of all horizontal dimensions to find the perimeter, then multiply by the height to find the square footage. |

ESTIMATING VINYL SIDING

|

|

|

|

|

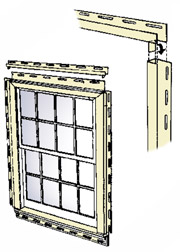

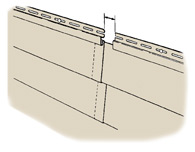

FIG. 4 - Take extra care to make sure your baseline is level, then install the starter strip. Leave a 1/4" gap wherever the ends meet.  FIG. 5 - Cut a tab in the end of the J-channel over a door or window, then bend it into the side channel to form a rain drip.  FIG. 6 - Panel ends should be overlapped away from prevailing traffic, either 1" or according to the manufacturer's specifications. |

INSTALLING VINYL SIDING

|

|

|

|

Inside Corner Posts

Outside Corner Posts

Undersill Trim

Hammer

Chalk Line

Steel Tape Measure

Utility Knife

Straightedge

Tin Snips

Level

Line Level

Circular Saw

Fine-Toothed Blades

Galvanized Roofing Nails

Snaplock Punch

Nail Hole Punch

Unlocking Tool

Hacksaw

Ladder

Carpenter's Square

Felt Tip Pen

Mason's Line

Sawhorses

| Check your state and local codes before starting any project. Follow all safety precautions. Information in this document has been furnished by the National Retail Hardware Association (NRHA) and associated contributors. Every effort has been made to ensure accuracy and safety. Neither NRHA, any contributor nor the retailer can be held responsible for damages or injuries resulting from the use of the information in this document. |