|

||

|

||

|

|

|

||

|

||

|

|

The basics of panel installation are the same, even when the panel styles require a slightly different method.

Inside this document you will find information about:

|

ESTIMATE YOUR NEEDS

|

|

|

|

|

CONDITION THE PANELS

|

|

|

|

|

PREPARE THE WALLS

|

|

|

|

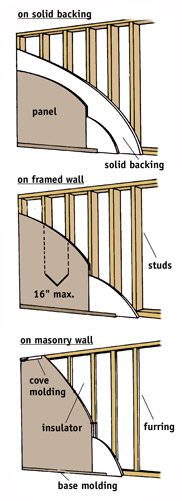

FIG. 1 - Paneling may be installed to solid-backed walls, over studs or over furring strips. |

INSTALLING ON SOLID BACKING

|

|

|

|

|

INSTALLING ON A FRAMED WALL

|

|

|

|

|

INSTALLING ON A MASONRY WALL

|

|

|

|

|

FIG. 2 - Furring strips should be placed 16" apart horizontally or vertically. Put blocking every 4 ft. between furring. |

BEFORE PANEL INSTALLATION

|

|

|

|

|

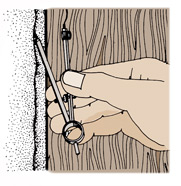

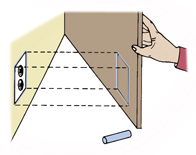

FIG. 3 - Snap plumb chalk lines at the center of all behind-the-wall framing.  FIG. 4 - To keep from getting ragged edges on the faces of panels, they should be hand-sawn from the finished side or saber-sawn from the backside.  FIG. 5 - Use a pencil compass to scribe irregular corners onto panels. Cut with a coping saw for a perfect corner fit.  FIG. 6 - Space the panels apart about the thickness of a dime to allow for expansion. |

MEASURING AND CUTTING THE PANELS

|

|

|

|

|

PANELING WITH NAILS

|

|

|

|

|

FIG. 8 - After contacting panel and adhesive, pull it away from the wall at the bottom. Wait for the adhesive to get tacky before recontacting. |

INSTALLING WITH ADHESIVE

|

|

|

|

FIG. 9 - Marking cutouts for electrical boxes is easy if you chalk the box edges and make contact with the panel in position.  FIG. 10 - Drill four holes at the corners of the box, then make the cutout with a fine-toothed keyhole saw. Add 1/4-inch all around. |

FITTING ELECTRICAL BOXES

|

|

|

|

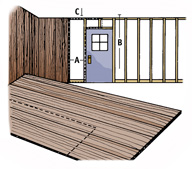

FIG. 11 - To make the waste cutout in a panel at an opening, measure a, b, c, then transfer these measurements to the face of the panel. |

INSTALLING AROUND DOORWAYS

|

|

|

|

|

FINISHING TOUCHES

|

|

|

|

|

|

|

| Nails (several sizes) | Fine-toothed Saw |

| Tape or Rule | Level |

| Knife | Plumb Line |

| Drill and Bit | Keyhole Saw |

| Carpenter's Square | Miter Box |

| Straightedged Rule | Chalk or Crayon |

| Chalk Line | Powdered Chalk |

| Pencil Compass | Coping Saw |

| Panel Adhesive | Plastic Film or Waterproof Paper |

| Masonry Waterproofing | Drop-in Caulking Gun |

| Furring Strips | Shingle Scraps |

| Masonry Bit and Anchors | Furring Strip Adhesive |

| Moisture-Resistant Primer | Moldings |

| Nail Set | Color-Matched Putty Stick |

| Marking Pen | Stain |

| Paintbrush | Stud Finder |

| Saber Saw | |

| Check your state and local codes before starting any project. Follow all safety precautions. Information in this document has been furnished by the National Retail Hardware Association (NRHA) and associated contributors. Every effort has been made to ensure accuracy and safety. Neither NRHA, any contributor nor the retailer can be held responsible for damages or injuries resulting from the use of the information in this document. | |