|

||

|

||

|

|

||

|

||

|

||

|

|

||

Laminated plastics are available in many colors, patterns and designs. They can be used for countertops, tabletops and many other surfacing applications. The sheets are available in dull or gloss finish.

Laminated plastic is made from layers of paper that are first impregnated with resin and then bonded together under pressure and high temperature, forming a rigid sheet.

Inside this document you will find information about:

|

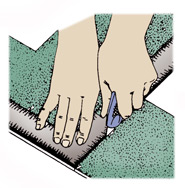

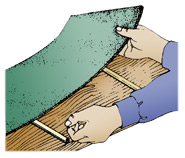

FIG. 1 - Sand and clean the surface before applying plastic laminate. |

PREPARING THE SURFACE FOR LAMINATE PLASTIC

|

|

|

|

|

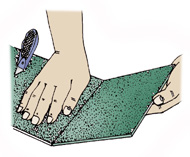

FIG. 2 - You can cut plastic laminate with a regular circular power saw and a fine-tooth blade.  FIG. 3 - Plastic laminate can be cut with a utility knife or using special laminate blades.  FIG. 4 - The laminate will snap after it is scored.  FIG. 5 - You can cut plastic sheets with a fine-tooth hand saw. |

CUTTING LAMINATED PLASTIC

|

|

|

|

|

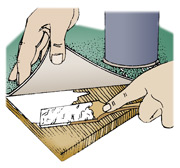

FIG. 6 - Brush contact cement over the counter surface after sanding and cleaning it.  FIG. 7 - Apply two or three coats of contact cement on any trim strips along the counter edges.  FIG. 8 - You can use a handmade wood paddle for spreading the contact cement.  FIG. 9 - Use pieces of dowel rod to position the sheet of plastic laminate.  FIG. 10 - On large areas, longer dowel rods are needed to hold the laminate away from the cemented surface.  FIG. 11 - Sheets applied to vertical areas do not normally require a protective shield of paper. |

APPLYING LAMINATED PLASTICS

|

|

|

|

|

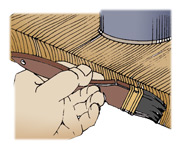

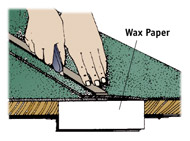

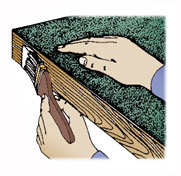

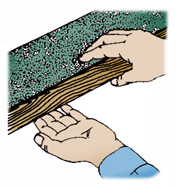

FIG. 12 - Use a roller to apply pressure to the newly laid sheets.  FIG. 13 - Place a strip of waxed paper along the joint area.  FIG. 14 - After applying two coats of cement to edges, apply one coat to back of laminate.  FIG. 15 - Place the edge strip into position carefully.  FIG. 16 - On long spans, apply pressure to edge strips in the center and work to the edges.  FIG. 17 - Edge stripping should be slightly wider than the edge to be covered. The extra width goes at the bottom.  FIG. 18 - Hold the router firmly with both hands and move slowly. |

FINISHING OFF THE JOB

|

|

|

|

Fine-Tooth Hand Saw

Wooden Mallet

Paintbrush

Roller

Power Sander

Work Gloves

Steel Square

Dowel Rods

Sanding Block

Straightedge

Utility Knife

Hand Cleaner

Fine-Tooth Backsaw

Power Saw

Fine-Tooth Blade for Power Saw

File

Sandpaper

Check your state and local codes before starting any project. Follow all safety precautions. Information in this document has been furnished by the National Retail Hardware Association (NRHA) and associated contributors. Every effort has been made to ensure accuracy and safety. Neither NRHA, any contributor nor the retailer can be held responsible for damages or injuries resulting from the use of the information in this document.