|

FIG. 5 - Enlarge and

undercut a concrete wall crack with a cold chisel and hammer.

FIG. 6 - Clean the

undercut area with a stiff wire brush, but leave a rough surface.

FIG. 7 - Moistening

the area to be repaired prevents the newly applied patch from drying out.

FIG. 8 - Force the

concrete patch mix into the area with a pointing trowel.

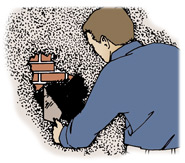

FIG. 9 - Repair holes

in concrete walls the same way you repair cracks.

|

REPAIRING CRACKS AND HOLES

IN CONCRETE WALLS

- Repairing a crack in a concrete wall requires basically the same steps

as repairing a crack in a sidewalk or driveway.

- The cracked area must first be undercut and widened in basically the same

way as previously described for a sidewalk (Fig. 2).

- The widening and undercutting can be done with a cold chisel and hammer

(Fig. 5). The width and depth of the undercutting depends on the size

and length of the crack.

- After all loose material has been chipped away, thoroughly clean the undercut

area around the crack with a stiff wire brush (Fig. 6). Do not brush

the area enough to smooth off the edges. The rough surface created by

the chiseling provides a good bond for the new concrete you'll apply.

- When the enlarged area has been thoroughly cleaned, apply cement adhesive

with a brush. This is the same cement adhesive used when repairing sidewalks.

If you do not have a cement adhesive, prime the area with a thin, creamy

mixture of Portland cement and water.

- In some cases, you can make the patch by simply moistening the area thoroughly

before filling the crack with concrete (Fig. 7). Although the moistening

is important, a concrete adhesive or the mixture of Portland cement

and water is much more desirable than moistening with water only.

- You can use a ready-mix concrete patch for small cracks in cement walls.

Force the mixture into the cutaway area with a pointing trowel (Fig.

8). Be sure to use enough pressure to force the patch mix into all the

cutaway areas in the crack.

- It may be difficult to conceal the patch, since the finish on the old concrete

is difficult to duplicate. To conceal the patch, simply experiment with

matching the original finish by roughing up the patched area while it

is still workable. Try using an old broom, a float, or any other tool

to create the desired rough finish.

- You can patch holes and broken areas in concrete walls by simply clearing

out the hole in the same basic way you would undercut a crack.

- After the hole has been thoroughly cleaned and cut away, apply the cement

adhesive and insert the patch mix into the hole with a pointing trowel

(Fig. 9).

- Moisten the area and cure it after the patch is applied in the same way cracks in cement driveways or sidewalks are moistened and cured.

|