Before tackling any maintenance or repair, check your driveway for these conditions:

Impressions left by car tires after the car has been parked on the drive overnight.

This is an indication of poor construction.

Heaving or tilting during cold weather, or buckling or cracking with the spring thaw.

These are signs of poor drainage.

To repair these troubles, you'll need a new driveway. Fortunately, such problems are

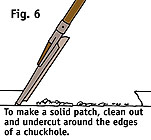

not common. More likely problems are minor cracks, crumbling and chuckholes, which are

relatively easy to repair.

The procedure and materials used depends on whether you're repairing cracks, filling

low spots, patching or seal-coating your driveway. Your local retailer can help you select

the products you need for making repairs.

|

REPAIRING

CRACKS REPAIRING

CRACKS

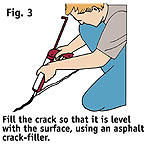

- You should fill any cracks in a blacktop drive as soon as possible to keep water from

getting under the slab and causing more serious problems. Cracks that are 1/2" and

wider are filled with asphalt cold-patch, sold in bags and cans. Narrow cracks are treated

with crack-filler, which is available in cans, plastic pour bottles and handy caulking

cartridges.

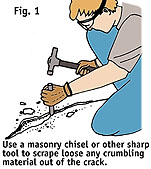

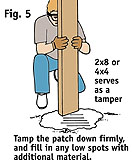

- Use a masonry chisel, wire brush or similar tool to dig away chunks of loose and broken

material from the crack (Fig. 1).

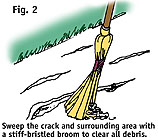

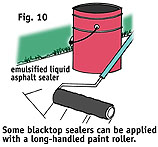

- Sweep out the crack with a stiff-bristled broom (Fig. 2). Your shop vacuum will

also work well.

- Use a garden hose with a pressure nozzle to clean off all dust. If the area is badly

soiled or covered with oil or grease drippings, scrub it with a strong commercial driveway

cleaning agent. For a patch to adhere, the crack must be free of all such things. After

using a cleaner, rinse the area with water.

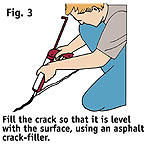

- For a deep crack, fill it to within 1/4" of the top with closed-cell plastic backer

rod or sand before applying a patching compound.

- Apply the crack-filler (Fig. 3).

|

|

FILLING

DEPRESSED AREAS FILLING

DEPRESSED AREAS

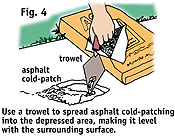

- Depressed areas, sometimes called "birdbaths," cause water puddles on the

driveway. If not too deep - less than an inch - these areas can be filled so they're even

with the surrounding surface. Sweep away all dirt, hose down the area, and remove any oil

or grease by washing with a detergent or cleaner.

- The surface may be slightly damp when applying the patching material, but make sure

there is no standing water.

- To help the new material adhere to the old, prime the area with emulsified liquid

asphalt, which is often simply called "driveway coating."

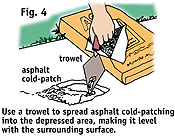

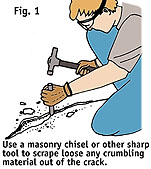

- Then, use a trowel to spread asphalt cold-patching material into the depression, filling

it level with the surrounding surface (Fig. 4). Smooth the patch, then tamp it with

a metal tamper or a 5' to 6' length of 2x8 or 4x4 lumber. Used vertically (Fig. 5),

the lumber has the surface area and weight for successful tamping.

- Allow your blacktop patch to dry for 24 hours before seal-coating the entire driveway.

|

|

SEALING THE

DRIVE SEALING THE

DRIVE

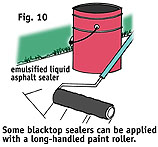

- Use a sealant to coat blacktop surfaces every few years. The ideal time to seal your

drive is after you have completed any repairs. Sealer gives a fresh, new look to a

driveway. And it does more than that - it provides protection from sun and moisture and

from grease, oil and gasoline drips and spills, as well as other damaging substances.

Sealer guards against everyday wear and tear. It also fills hairline cracks that aren't

serious enough to require individual patching.

- The blacktop surface must be clean before you apply sealer. This includes dust, dirt,

grease, oil, and debris. Sweep it clean. Remove grease and oil spots with detergent or

cleaner. End the cleaning by rinsing the area thoroughly with water. Squeegee water from

any puddled spots. It is not necessary that the surface be thoroughly dry before applying

the sealer, but don't do the job when rain is forecast.

- Stir the sealer to make sure its ingredients are well-blended.

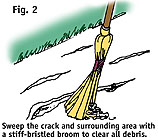

- Some sealers can be applied with a long-handled paint roller (Fig. 10). However,

the best tool for this is a combination squeegee/broom made for the purpose and available

from your retailer (Fig.11). Apply the sealer only to a small area of the driveway

at a time. Pour it out and spread it around evenly with the squeegee, brush or roller.

Don't spread the sealer too thin - one good coat stands up for a long time. Allow small

cracks and weathered areas to drink in the sealer.

- Be very careful to avoid splashing sealer onto walls, garage doors and yourself.

Moreover, plan the project so you will not have to walk across the treated areas. Use care

- this material can make a mess of house floors.

- Improve traction on sloped areas by adding sand to the sealer mix. Stir it in thoroughly

before applying, and keep the mix stirred during application.

- You can sprinkle sand over a sealer surface that's still wet. Excess sand not captured

by the sealer can be swept up later.

- Allow the sealer to cure for 24 hours before using the driveway (products vary in the

setting times, so check to see what's required by the one you use.) Erect string barriers

at the street end of the drive to remind family members to keep off and to discourage

casual traffic from spoiling your efforts.

|

| ASPHALT SAFETY CHECKLIST |

| When working with any asphaltic material, avoid

prolonged contact of the material with your skin. |

| Excessive breathing of asphalt materials should be

avoided, too. |

| Wear heavy work gloves, old clothing and old shoes if

you want to be protected from asphalt spatters. |

| When chipping or chiseling old blacktop, wear eye

protection. Also, don't chisel with a carpenter's hammer, because it isn't designed for

this type of job and its face may chip. Instead, use a hand-drilling hammer or machinist's

hammer. |

| Keep all asphalt materials away from high heat. Keep

solvent-thinned materials away from open flames. |

| Close containers after each use. |

| Always follow the manufacturer's instructions for the

product you are using. |

TOOLS AND MATERIAL CHECKLIST

| Asphalt Crack Filler |

Shop Vacuum |

Asphalt Cold-Patch |

Trowel |

| Emulsified Liquid Asphalt |

Stirring Stick |

Driveway Cleaner |

Tamper |

| Detergent |

Garden Roller |

Squeegee/Broom |

Long-Handled Paint Roller |

| Masonry Chisel |

Long-Nap Roller Cover |

Hand-Drilling or Machinist's Hammer |

Closed-Cell Backer Rod |

| Shovel, Spade |

Rope Oakum |

Stiff-Bristled Broom |

Sand |

| Garden Hose |

Gravel |

Pressure Nozzle |

Wire Brush |

REPAIRING

CRACKS

REPAIRING

CRACKS

FILLING

DEPRESSED AREAS

FILLING

DEPRESSED AREAS

PATCHING

CHUCKHOLES

PATCHING

CHUCKHOLES

SEALING THE

DRIVE

SEALING THE

DRIVE